The additive manufacturing system of SBI - the M3DP

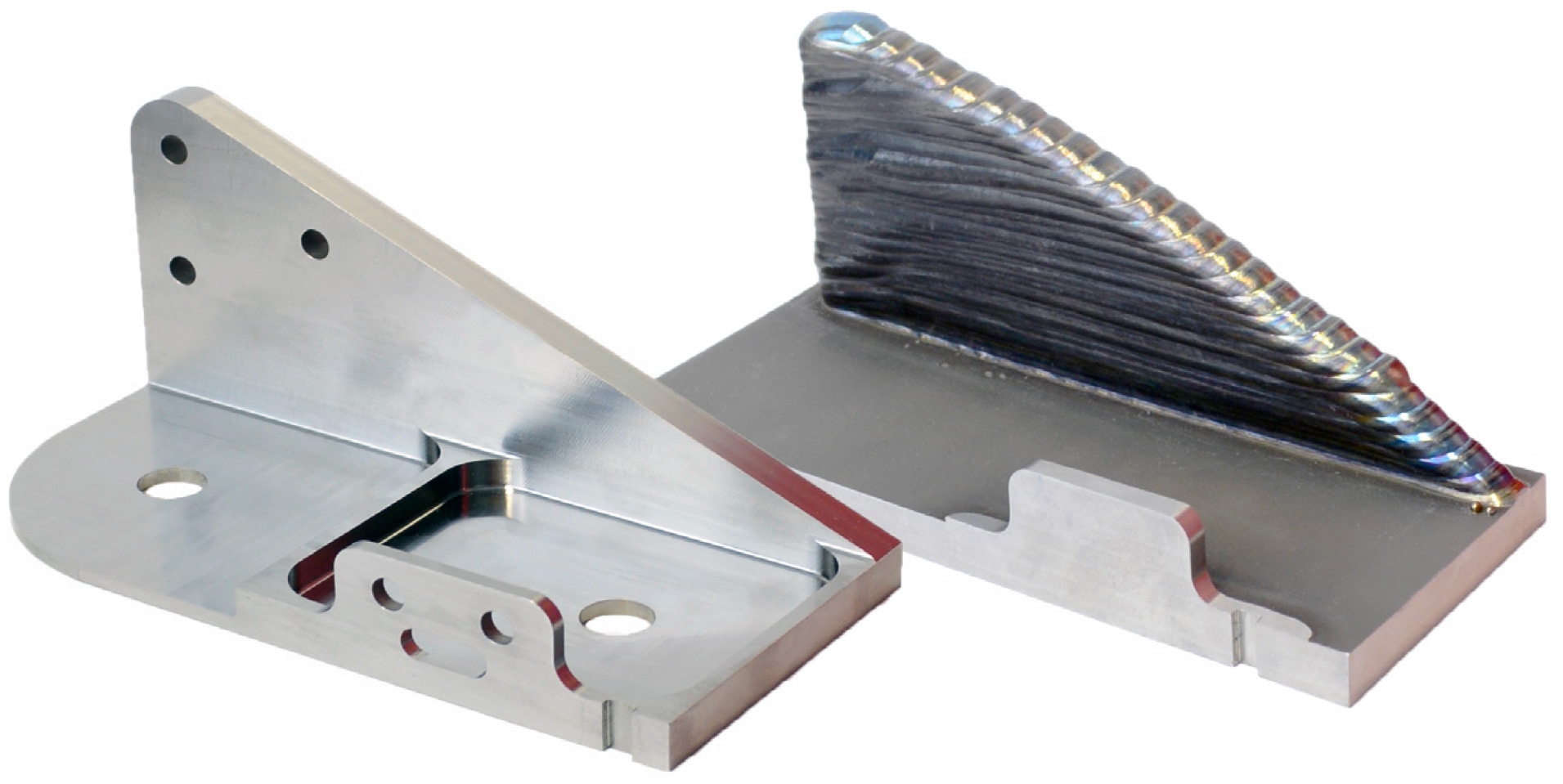

The M3DP stands for Metal 3D Printer and is designed to process parts

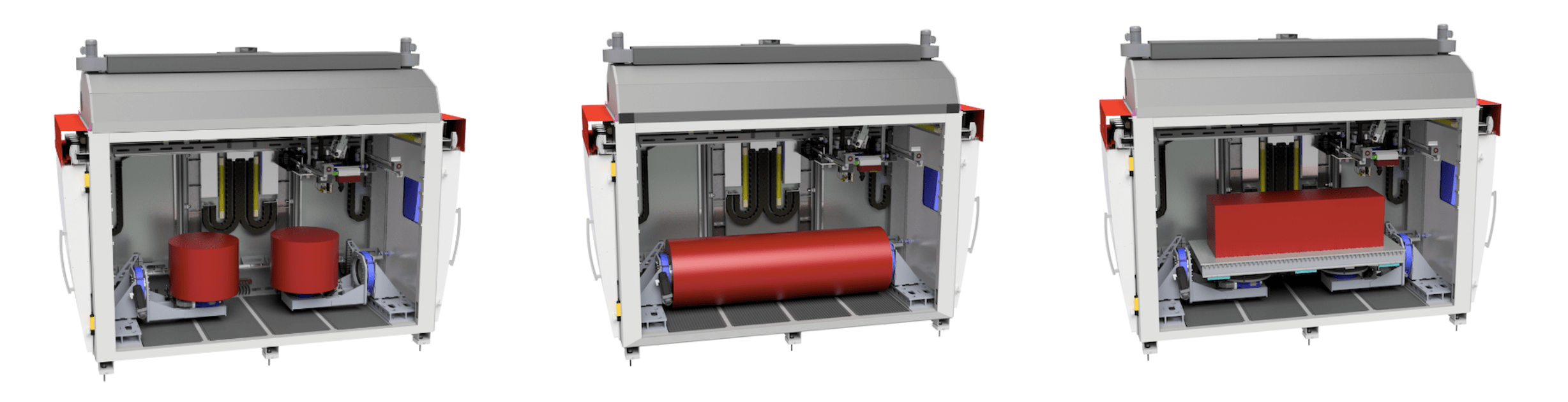

The M3DP is a modularly configurable AM system and can be adapted to specific requirements. Whether 2.5D configuration, 3D configuration or rotary configuration, the possibilities of the M3DP offer many solutions.The M3DP is a modularly configurable AM system and can be adapted to specific requirements. Whether 2.5D configuration, 3D configuration or rotary configuration, the possibilities of the M3DP offer many solutions.

To protect the M3DP from harsh workshop conditions the frame and the shell of the system are made of stainless steel and are visually enhanced by a design cover.

For working with oxygen & moisture sensible materials – i.e. titanium - the M3DP can be upgraded by an airtight roof construction. With that option the air inside the complete work-volume can be purged and replaced by an inert gas like argon which excludes oxidation processes.

The system is flooded with inert gas through the floor and is designed in such a way that only a small amount of turbulence occurs in order to make the filling process as efficient as possible.

The M3DP is designed to supply two or more wires into the melting pool, advantages in terms of process reliability and process technology entail.en. On the one hand, smaller wire diameters can be used, which favors the melting speed, on the other hand, the speed of the individual wires can be reduced and thus the process reliability is increased. A supply of several wires also brings the possibility to supply wires of different composition and thus produce specifically local alloys.

The plasma arc is analogous to the TIG arc, an arc that burns between a non-melting electrode and the workpiece. As a result, arc energy and wire supply are decoupled and independent of each other. Due to these properties, the plasma arc can be optimally coordinated with material and temperature management. In addition, the decoupling allows preheating of the workpiece or substrate as a process option to process temperature-sensitive materials such as nickel-based alloys.

The printing process is continuously monitored, for example, the arc and the melting bath are detected by a camera and linked to the most important process parameters such as arc current and voltage. At a later time, the process can be analyzed and optimized based on it.

In addition to steels, the M3DP's range of materials to be processed is also nickel base alloys, copper, aluminium & titanium.

CAPRICORN

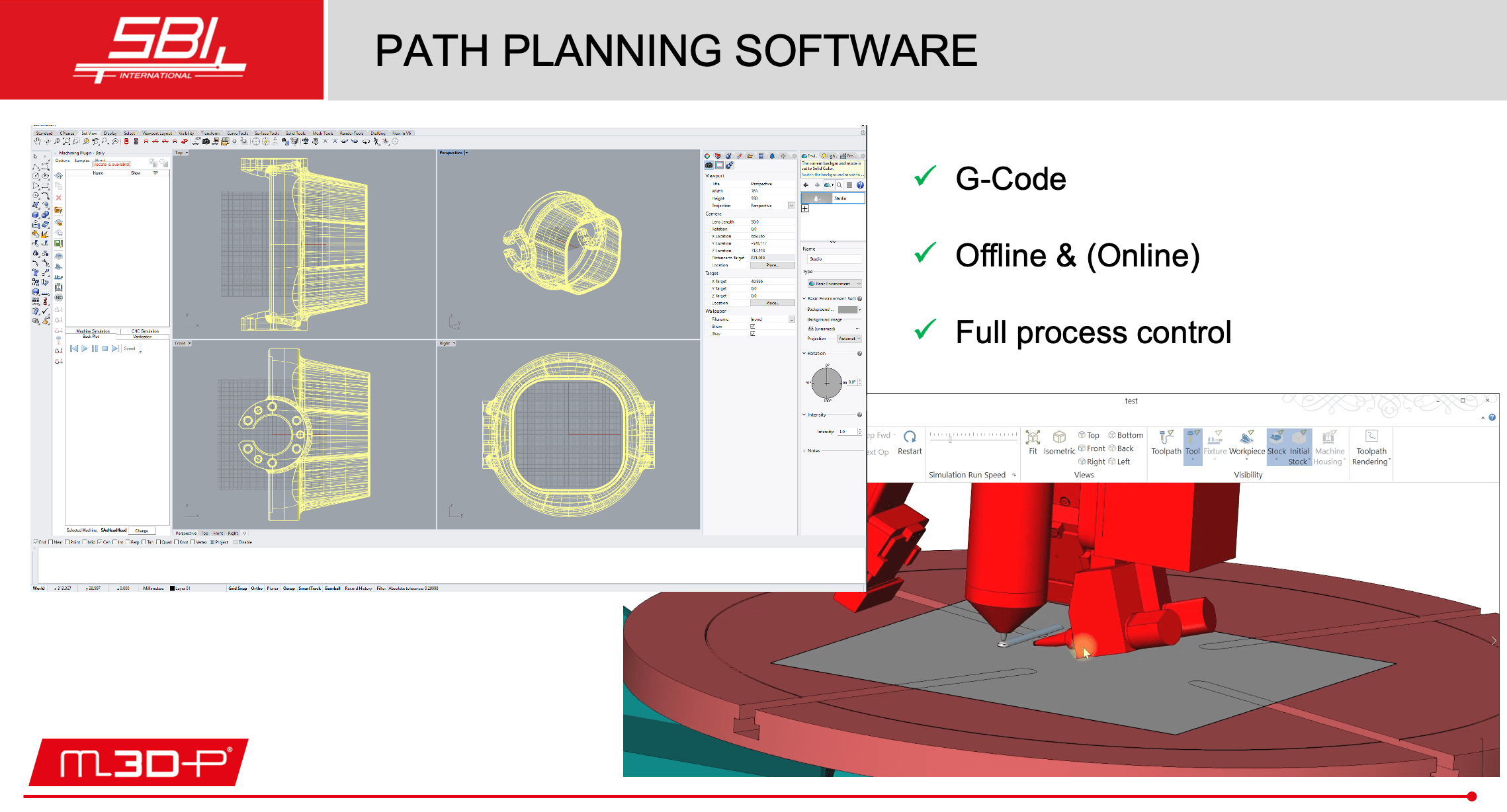

3D manufacturing by additive processes. CAPRICORN is our software solution for CAD file optimization, slizing and path planning.