COBOT your buddy for repair and repeated precision welding

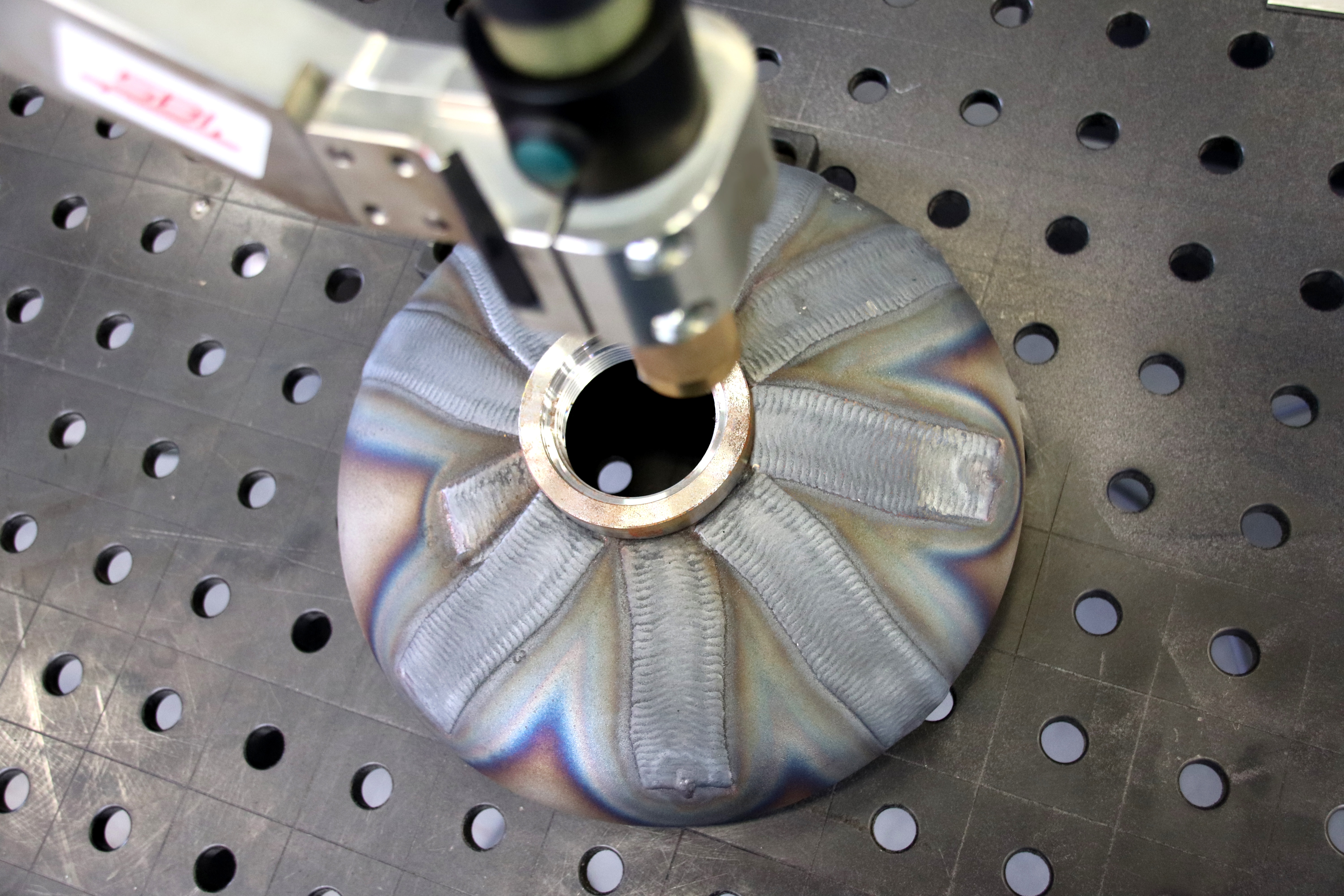

When repairing tools in the area of forging, cutting and stamping technology, a new wear layer is often applied using plasma powder technology.

For this purpose, the component usually has to be preheated in order to later correspond metallurgically. This sometimes very high radiant heat represents an additional complication for the manual welder.

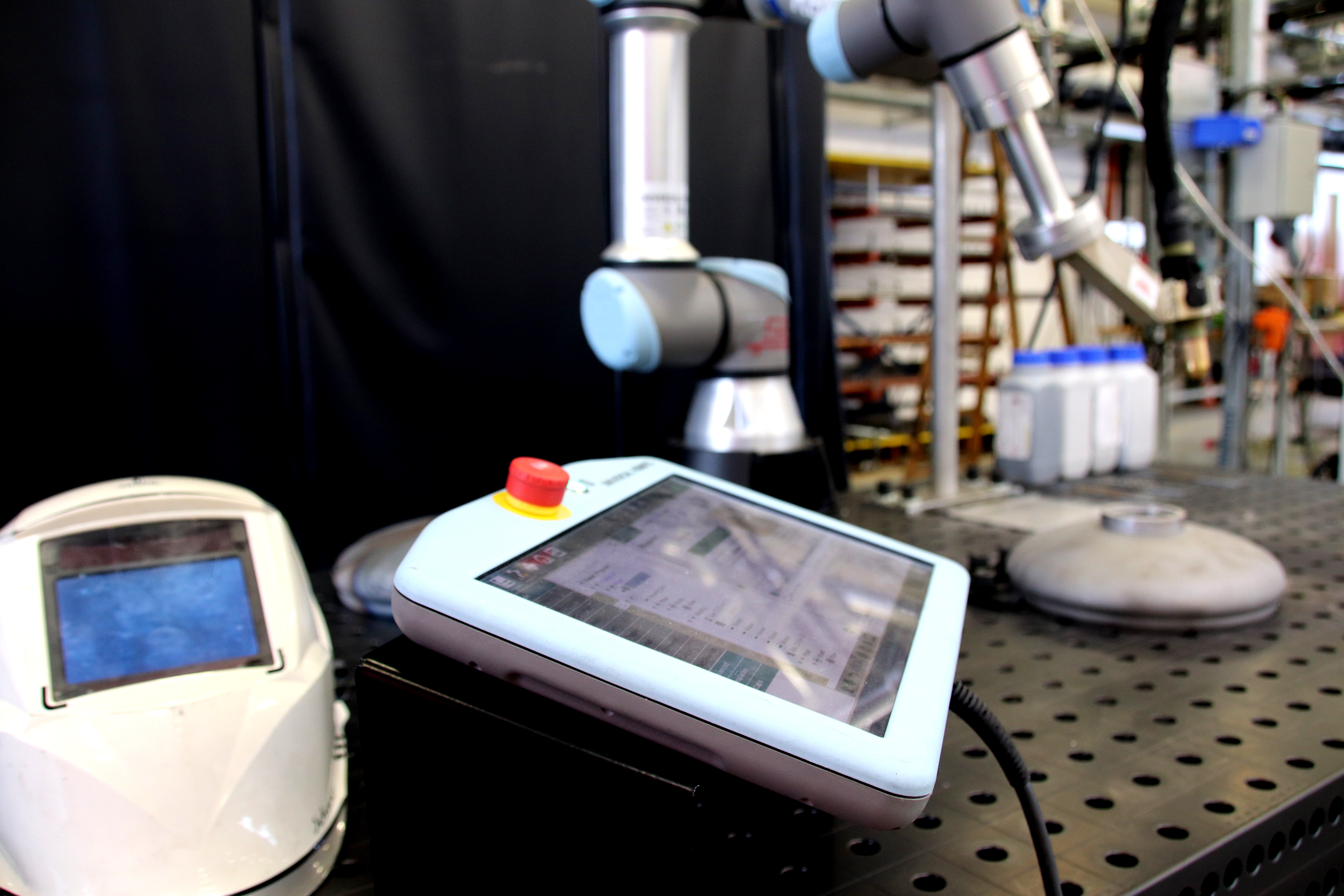

Solution: Using a cobot to guide the torch.

Due to the simple programming compared to a standard robot, even single pieces can also be manufactured profitably with all the advantages that mechanization offers compared to manual welding.

Repeatable results from the first part manufactured or repaired.

With the SBI COBOT solution, it's as easy as drawing a line with a pencil to program the weld path for the PLASMA Cladding Torch! No skilled PC programming or robot operation is required. Any operator can use our point-to-point teaching system by simply following the to be cladded area and starting the weld cycle immediately.