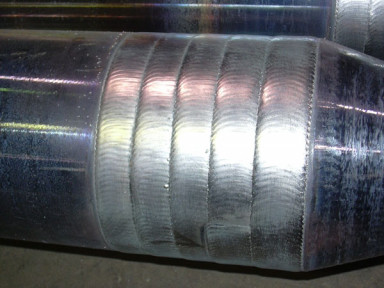

Intake Manifold

The main driver in automotive - beside quality and repeatability - is cycle-time. Produce as much as possible in short time. For welding of small components, we offer the perfect solution to meet this requirement with our patent Plasma Spot Welding process.

Read more …