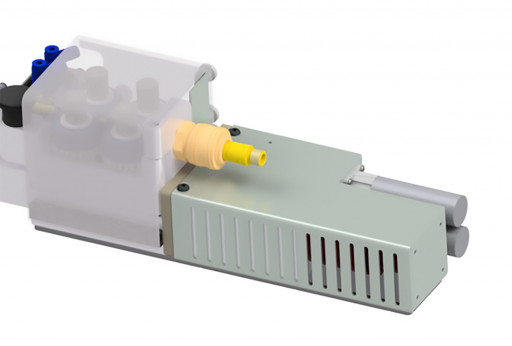

With the newly developed master wire feeder or wire feed unit, a compact design was achieved due to the design, as the drive is carried out via the BLDC or DC motor directly on a worm wheel and thus a large structure was kept small from the start. Furthermore, with the pneumatic clamping mechanism and a clear and easily accessible surface structure, a quick and effortless wire changing system could be developed, as different additional materials or welding wires are being used more and more often these days. Knurled screws were used to fasten the wire reels so that they could be changed without tools. In terms of performance data, a tensile force of at least 15kg was achieved, with the curve for an aluminum wire being at least 18kg. These values result from a contact pressure of the cylinder of 4 bar.