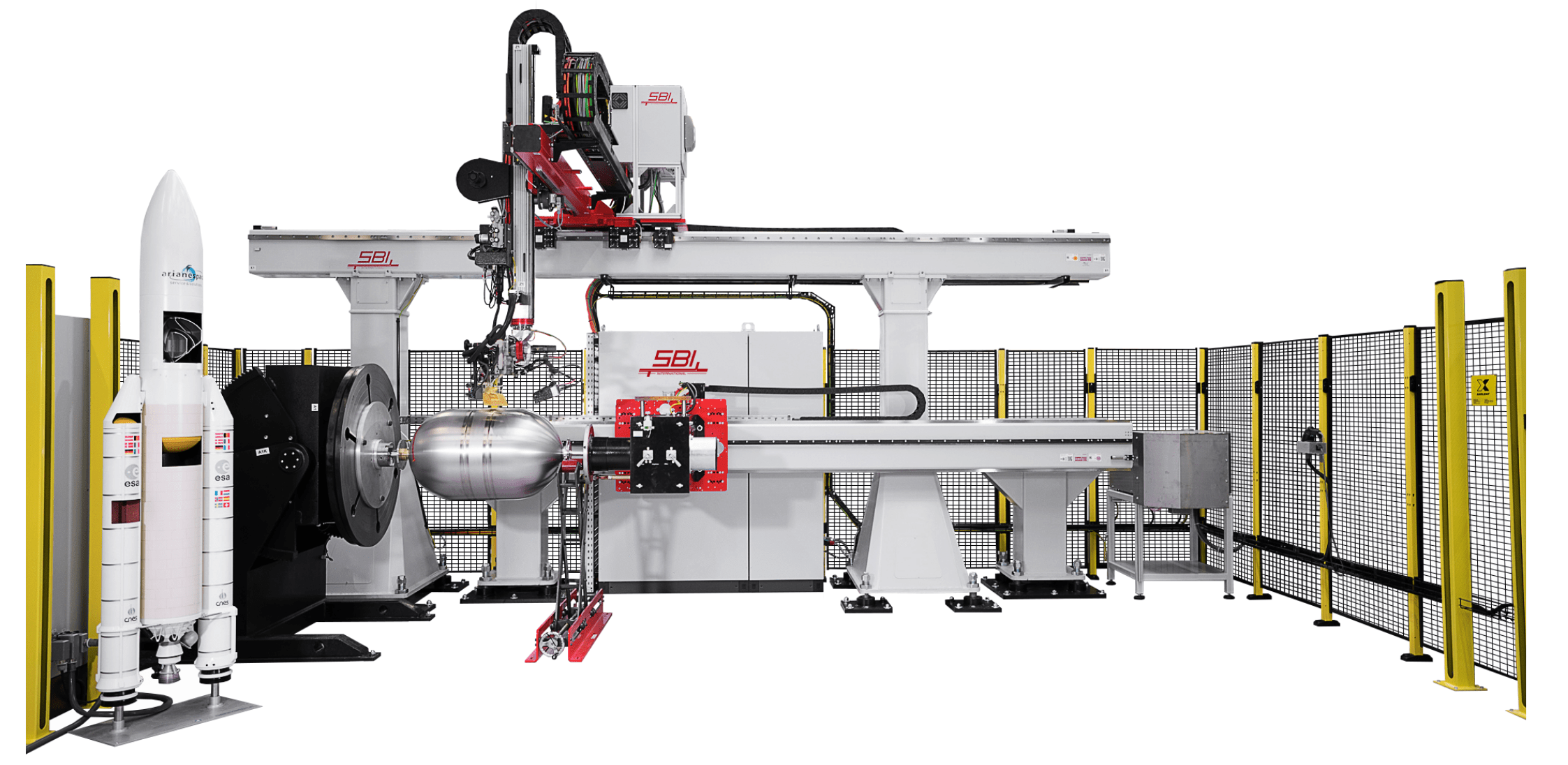

Joint welding of satellite propellant tank

Satellite propellant tanks are often made of titanium due two reasons.

First titanium offers a great specific strength and second it has good corrosion resistance.

Lifting a mass of 1kg into the orbit is not a bargain - starting at 2,500€ and rising up to several 10,000€ depending on the orbit height. To save weight and therefore money for the rocket start, propellant tanks of satellites are made of thin titanium sheets with a thickness between 0.8-1.2mm. This thin titanium skin acts as a tight membrane. To withstand the enormous pressure resulting due the gauge pressure and the evacuated space, the titanium membrane is wrapped by carbon or glass fibre reinforced plastic layers.

The welding of the titanium sheets can be done by Plasma Welding with or without a filler wire. Argon, which is used for shielding gas, trailing gas and forming gas, protects the liquid weld pool during the Plasma Welding process from atmospheric conditions and keeps the seam safe and clean.